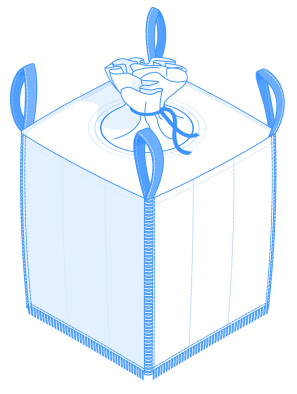

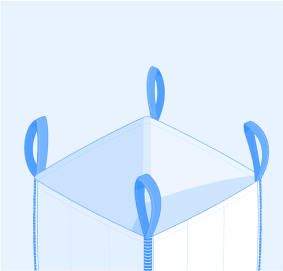

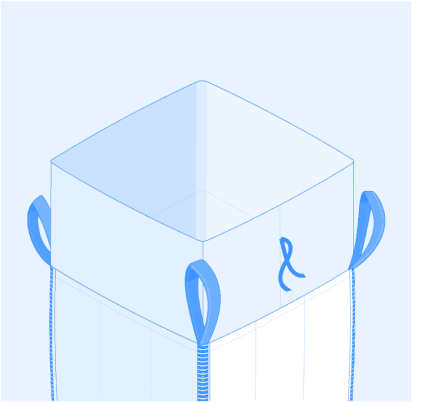

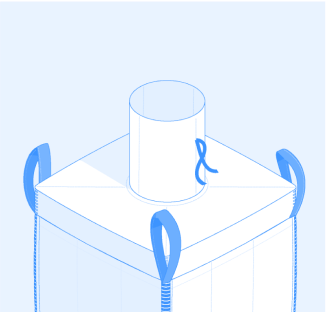

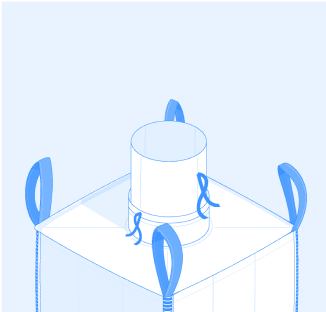

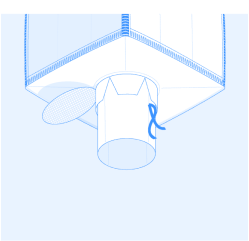

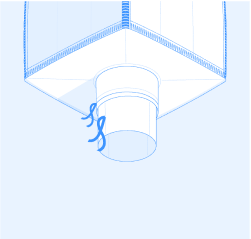

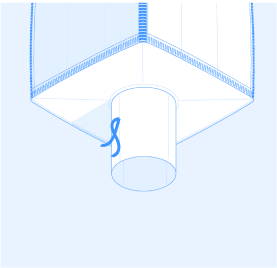

Our extensive range of 4-Loop FIBCs (Flexible Intermediate Bulk Containers)serves a wide variety of dry bulk handling applications, providing you with safe and sturdy semi-bulk packaging solutions. For over a decades, the world's most important products have traveled safely around the world with our PrimaCon industrial packaging. We are committed in bringing you the best customized products through a comprehensive and innovative product portfolio.

The unique construction of our FIBCs help to prevent deformation of the bags and it ensures the shapes of the bags during transportation and storage.

Significant benefits come with the use of FIBCs:

- Optimized transport loading

- Improved space utilization during warehouse storage

- Improved stability during stacking, transportation and handling

- Increased safety within the immediate environment of the FIBCs

Contact us now to inquire about our PrimaCon!