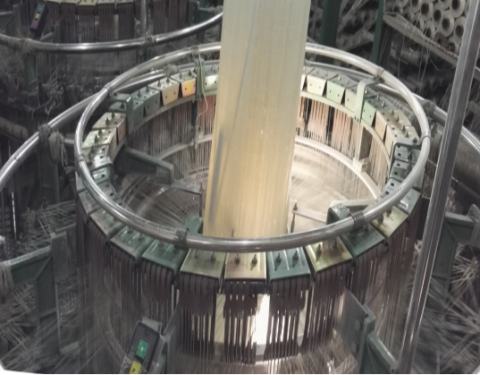

Maintenance

Precise and effective maintenance are not only a cost-cutting measure but also an investment for our company’s future. Our technicians have the knowledge and the expertise in handling equipment breakdowns as we continue to train more staffs in reducing unexpected maintenance costs – which is the least of a business need.

- Our technicians are committed to a preventive maintenance program to help anticipate change, wear, and tear.

- Corrective actions are taken continuously to ensure reliability and performance, minimizing unscheduled downtime caused by equipment breakdown.

- We consistently train knowledgeable machinery operators to reduce the likelihood of equipment breakdowns.